Combustion air always contains dirt particles and impurities which must be prevented from reaching the inside of the engine. A highly effective air filter is, therefore, essential to protect the engine and engine components like the turbocharger and mass air flow sensor against wear and tear.

Ashra has the expertise to develop high performance filters made to meet stringent customer requirements. Ashra uses rigorous laboratory tests, simulations and special software to improve our filters. Our highly qualified team of expert engineers are focused on delivering excellence in terms of product technology through continuous innovation. They run through several rigorous prototype cycles to test key design factors like stress, fatigue life and performance to ensure best-in-class quality, efficiency and reliability.

Our engineers are continuously designing and developing new filters to meet the specific requirements of our customers. Our laboratories are equipped with the latest generation technologies for the study and analysis of each component of a filtering system. With our ability to perform comparison tests and specific analyses, we are continuously innovating to improve the efficiency and performance of our solutions, thereby guaranteeing the continued reliability of our products.

Our filters are stronger, more durable and have higher dust holding capacity than most others. With Ashra’s industry-leading technology, you get optimized filter performance and peak efficiency, resulting in lower operating costs.

Continuous innovation is key to our quality and cost effectiveness, so incremental improvement ideas in key products are evaluated and implemented every year, with the result that our product quality remains easily comparable to that of large MNC filter manufacturers.

Ashra’s R&D lab was the first to be set up in the country and continues to support us with the equipment required to test our range of filters to rigorous quality requirements.

The result — we are direct on line suppliers to most of our customers.

Customer needs drive Ashra Consultants' internal processes in product development quality and delivery.

Filter testing facilities are available at our captive laboratory. Filters are tested for Flow Rate, Pressure Drop, Efficiency, Dust Holding Capacity etc. as per standard test procedures.

Media used in the filtration systems are tested for Permeability, Porosity, Pore Sizes, Burst Strength etc.

Filters are developed after complete testing of the media used and as well as testing of the final/finished product as specified by the customer.

Customer needs drive Ashra Consultants’ internal processes in Product Development, Quality and Delivery.

Ashra Filters and Air Oil Separators (AOS) are designed to trap the contaminants in Air or Fluid and prevent them from damaging the downstream engine by wear and tear. At the same time, we ensure that no excessive restriction is built up across the filter or AOS. For AOS the filtration media are very carefully selected so that they separate oil and water present in compressed air in any form — vapour, liquid or aerosol. Thus the downstream compressed air is free of these contaminants.

For Air Filters and Liquid Filters again, specific media appropriate to their application are selected to ensure effective and efficient working of the filters.

To maintain and ensure sustainable quality of paper and media, maximum quantum of Ashra media is sourced from reputed suppliers abroad. Each supply of paper / media is tested before being released to production.

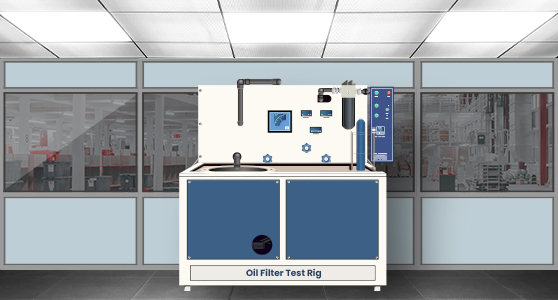

Comprehensive test facilities for internal use are available at our R&D centre. A newly designed filter is first validated for its performance in the R&D laboratory and only then is it released for production. Validation or performance tests are performed according to the appropriate national or international test standard.

Ashra Consultants Pvt Ltd. has established an independent R&D unit specifically for testing of Filters and Filter Paper / media.

The R&D Laboratory is equipped to carry out the following types of tests:

All Paper/Media are tested for characteristics like Basis Weight, Thickness, Porosity, Permeability, Mean and Max Pore sizes.

Our test rig is designed as per ISO 5011 and tests are performed to determine the Clean Pressure Drop, Dust Holding Capacity and Filtration Efficiency. We have the capability of testing Air Cleaners upto 2500 m3/hr flow rate.

Hydraulic/Lube Filter test rig designed as per SAE - HS 806 for testing of oil filters is used to test Clean Pressure Drop, Media Migration, Dust Holding Capacity, Filtration Efficiency (gravimetric) at regular intervals, Collapse Pressure Drop, Relief Valve Opening Pressure etc.

Fuel Filter test rig designed as per SAE 905 specifications for testing of fuel filters is used to test Clean Pressure Drop, Media Migration, Dust Holding Capacity, Filtration Efficiency (gravimetric) at regular intervals, Collapse Pressure Drop and Relief Valve Opening Pressure etc. In addition, for Fuel-Water Separators, Water Separation Efficiency